Service Divisions

Crane Division

Our Crane Service Division has the capability and experience to handle all of your crane repair needs. The department is headed by a man who has spent months of cutting edge training at the Liebherr facility in Hamburg, Germany.

We can handle everything crane-related from replacing boom lacing to a full overhaul of hydraulic, electrical, and engine components. Straightening booms is no problem in our state-of-the-art facility in Long Beach, CA.

We can also do Category 3 and 4 inspection and repairs. With recertification services available as well.

It doesn’t matter if you need help with a boom truck or off-shore crane on a drilling platform. Contact us today to see how we can help get your equipment back up running as soon as possible. We are on-call 24 hours a day, 7 days a week.

Portable Service Division

Our portable service division can meet all of your welding and mechanical needs. With over 60 service trucks manned by the most experienced crews this industry has to offer, we are on-call 24 hours a day, 7 days a week.

We can provide a crew of any size to handle any discipline of welding you may need. All of our welders are LA City Certified with many supplemental certifications in;

- Certified Rebar Welding

- Certified Light Gauge Welding

- Certified Manual Welding

- Certified Semi-Automatic Welding

- FCAW Welding

- SMAW Welding

- SAW Welding

- GMAW Welding

We have serviced a variety of facilities from refineries, energy plants, and shipyards to luxury apartment lofts. There is no project we can’t handle. With facilities in Long Beach and Bakersfield California, we can be on-site in no time! Give us a call to see how we can assist you with your projects.

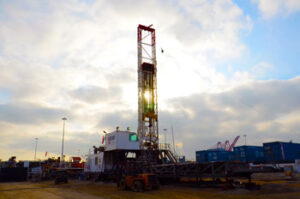

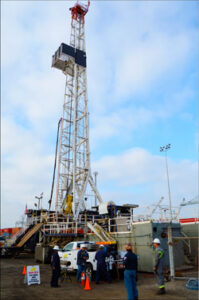

Rig Division

We have a state-of-the-art facility where we manufacture all aspects of drilling equipment. From cutting edge mud pumps with climate-controlled cabs to derricks engineered with safety and quality leading the conversation on design.

We have manufactured the following for very satisfied customers:

- Derricks

- Coil Tubing Units

- Mud pump Trailers

- Foamers

- Sub-Base Platforms

- BOP Hydraulic Handling Systems

- Stabbing Boards

- Tongs

- Pipe Racks

- Cable Trays

- Cable Spoolers

- Mud Pump Skids

- Anchor Blocks

- Torque Swivel Frames

- Tubing Boards

- Catwalks, Stairs, Platforms and Guardrails

- Storage Bins and Racks

- Doghouses

We have over 25 Rig Mechanic Trucks fully stocked to handle every aspect of oil field repair and maintenance. We are on-call 24 hours a day, 7 days a week.

Structural Steel Division

Our Structural Steel Division has participated in a variety of new building projects from the Red Bull headquarters in Santa Monica to The Plaza Towers in Irvine, CA.

Although we do new construction, our main specialty is the structural retrofit, major tenant improvement, facade upgrade, and adaptive reuse of existing buildings. Our projects include 21st Century Oncology in El Segundo, Marukome Miso Factory in Irvine, Japan Food Corporation Headquarters in Commerce, Church of Perfect Liberty in Torrance, Sketchers Store at Citadel in Commerce, and structural upgrades of TARGET Stores in various locations.

We can handle a wide range of projects ranging from one day in length engagements to year-long multimillion dollar contracts.

WHAT WE DO:

- Structural design and engineering

- Structural steel fabrication and installation for commercial, industrial, hospitality, churches and medical facilities.

- Column and beam frames

- Platforms and catwalks

- Floor and roof metal decking

- Roof screen and elevator guide frames

- Architectural storefront canopies or metal structures

- Perforated panels, expanded metals, wire mesh and grating

- Stainless, aluminum and carbon steel sheets

- Custom Stairs, rails and grills

- Gates and ladders

Sheet Metal Division

Our fully equipped Sheet Metal Division is housed in our front shop. We have welders from the Aerospace industry that can handle any and all of your exotic welding needs. This shop has worked on everything from custom Mobile Marketing trailers to Armored vehicles for the Long Beach Police SWAT department, and everything in between.

No job is too big or small for our Sheet Metal Division.

Our highly capable front shop is equipped to handle;

- Sheet Metal Fabrication and Welding

- Sheet Metal Forming

- Sheet Metal Rolling

- Sheet Metal Shearing

- TIG Welding

- MIG Welding

- Heli-Arc Welding

- Stainless Steel Welding

- Aluminum Welding

- Stainless Steel Railing

- Stainless Steel Piping

- Stainless Steel Tanks

- Aluminum Tanks

- Concentric Cones

- Repair of Exhaust Manifolds

- Repair of Industrial Valves

- Repair of Light Posts

- Repair of Tanks

- Custom Racks

- Laser Cutting

- Plasma Cutting

- Water Jet Cutting

- Copper Fabrication

- Bronze Fabrication

Spring Shop

Long Beach Spring is one of the oldest, continually running businesses in Long Beach. Established in 1922, they originally had a mix of leaf spring repair and modification and shoeing horses.

In our Spring Shop, we have a staff with a lifetime of experience. You never know what’s going to come to the shop. We’ve had NHRA drag racers, rare automobiles from Jay Leno’s collection, 1950s hot rods, modern rock crawling jeeps, and everything in the middle. Every vehicle leaves with the customer’s needs met.

We also specialize in new vehicle suspension for work trucks. Semis, Long Beach Fire trucks, school buses, etc.

Call or see us for a quote!

Additional Services

Consulting

We provide oil production and drilling equipment design from the crown to the ground. We promote innovative ideas to the oilfield industry by introducing new technologies that increase productivity and enhance safety.

Design & Engineering

Our full-service in-house engineering department offers in-depth knowledge, experience, and technical expertise across multiple engineering disciplines. We supply the necessary design, details, procedures, and materials to build your project, whether small or large in scale and simple or complex in nature. Our design calculations are prepared, approved, and stamped by a California registered structural engineer.

Project Management

CW Industries assigns a project manager to each project to guarantee customer satisfaction through field measurement, quality control, and job coordination.

Fabrication

Provide shop and field fabrication services for all oil field drilling, production, and well maintained equipment.

Non-Destructive Testing (NDT) Inspection

All fabrication and repair of steel structures for the oil field undergo rigorous quality control inspection of all-welded joints through magnetic particle (MP), ultrasonic (UT), and radiographic (X-Ray) inspections/examinations.